DON'T REPLACE IT. CLEAN IT!

Complete DPF Cleaning ONLY - $190.00

1 Hour Cleaning Service Available

Services

• Complete DPF Cleaning Service:

– Overnight – $190

– Same day – $260

• Recore DPF/DOC (replace ceramic part of the filter)

• Cleaning Service For DOC & SCR Filters

• Replacement of Gaskets & Clamps

• DPF/DOC/SCR Filters Reinstallation

• Detroit ONE BOX full Cleaning Service

• Full DEF System Service:

– DEF Cocsing Cleaning

– DEF Filters Replacement

– DEF Lines Replacement

– DEF Doser Replacement

– DEF Pamp Replacement

– DEF Leveler Replacement

• EGR Cooler Cleaning – $200

• NOX Sensors Replacement – $150

• Temperature Sensors Replacement

• Engine Carbon Cleaning (DCarbon)

• Force Regeneration

• Soot Level Reset

• Computer Diagnostic

• Troubleshooting

• Filters Miner Repair

• Filters Domestic Shipping

• Free Pick And Delivery For Mechanic Shops And Fleets 24 Hours Turnaround Time.

We do service for all makes and models of DPF/DOC/SCR filters, including all diesel engine equipment: buses, light, medium and heavy duty trucks, construction equipment, diesel generators, diesel cars and boats.

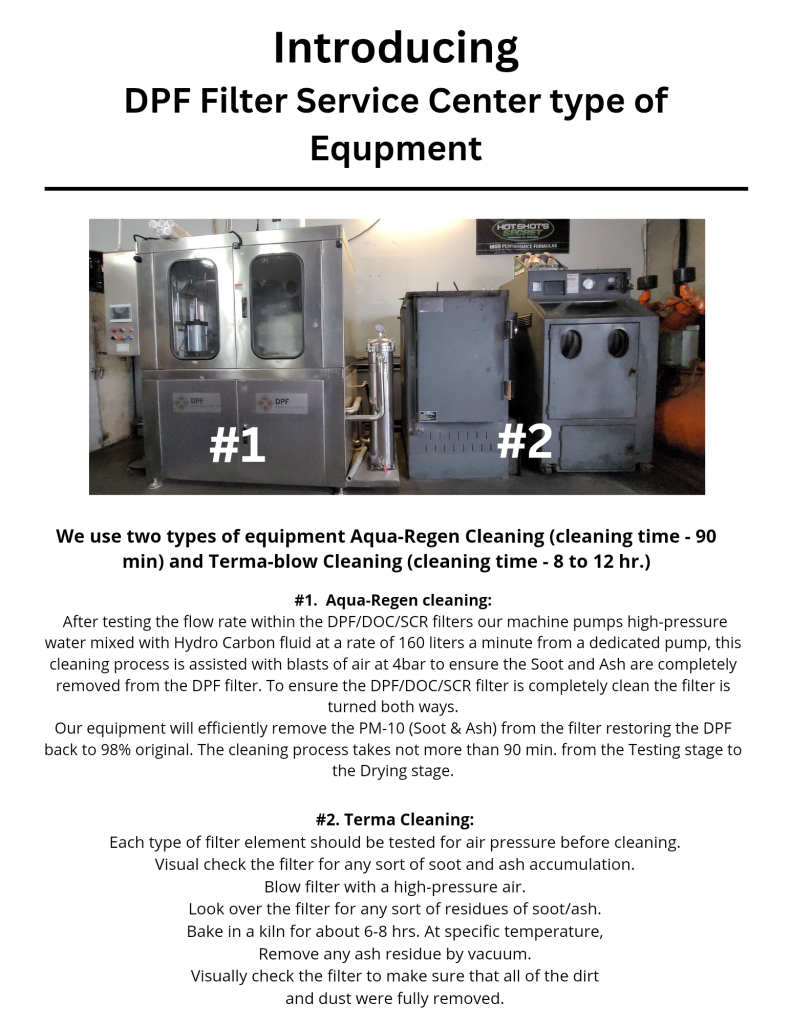

We clean Diesel Particulate filters more thoroughly than ever before. This is the only Diesel Particulate Filter cleaning system on the market that has extreme suction on the outlet side as well as pinpoint accuracy of forced air through the inlet side. We can ensure you there is no other DPF cleaning machine on the market that can get a DPF cleaned better than ours.

Service Bundles

VOLVO

DPF cleaning, DOC cleaning, 4 x gaskets, Diagnostic, Soot Level Reset, Labor (Not included clamps)

Price: $990

PETERBUILT

DPF cleaning, DOC cleaning, 4 x gaskets, Diagnostic, Soot Level Reset, Labor (Not included clamps)

Price: $990

KENWORTH

DPF cleaning, DOC cleaning, 4 x gaskets, Diagnostic, Soot Level Reset, Labor (Not included clamps)

Price: $990

ISUZU

DPF cleaning, DOC cleaning, 4 x gaskets, Diagnostic, Soot Level Reset, Labor

Price: $1200

HINO

DPF cleaning, DOC cleaning, 4 x gaskets, Diagnostic, Soot Level Reset, Labor

Price: $1250

INTERNATIONAL

DPF cleaning, DOC cleaning, 4 x gaskets, Diagnostic, Soot Level Reset, Labor (Not included clamps)

Price: $990

FREIGHTLINER

2 x DPF cleaning, DOC cleaning, 4 x gaskets, Diagnostic, Regeneration, Soot Level Reset, Labor (Not included clamps)

Price $990

Pickup Trucks

DPF cleaning, DOC cleaning, 2 x gaskets, Diagnostic, Soot Level Reset, Labor

Price: $1500

Cars

DPF cleaning, DOC cleaning

Call for price

Important Maintenance Tips

Tips To Keep Your DPF Filter Working Properly in Cold Wether And Never Get Stuck

AFTER TREATMENT SYSTEM

- Remove and clean the DOC and DPF filter.

- Replace the DEF dosing screen filter and in-line filter. Vehicles with 150,000 miles or more should have the DEF tank inspected for debris build-up. If debris is present, steam clean to remove debris at the bottom of the tank.

- Clean the Hydrocarbon Fuel Doser—complete every 125,000 miles. If you are getting close to the maintenance interval, perform this again before winter. (EPA10 only)

- Never shut off the truck when it is in the middle of the regeneration process.

- Top off DEF fluid prior to starting the truck so there is warm DEF in the tank. Remember that DEF fluid will freeze so it should be stored in a warm place above 40 degrees.

- If not currently running with an approved winter front or insulated DEF tank blanket, we highly recommend doing so.

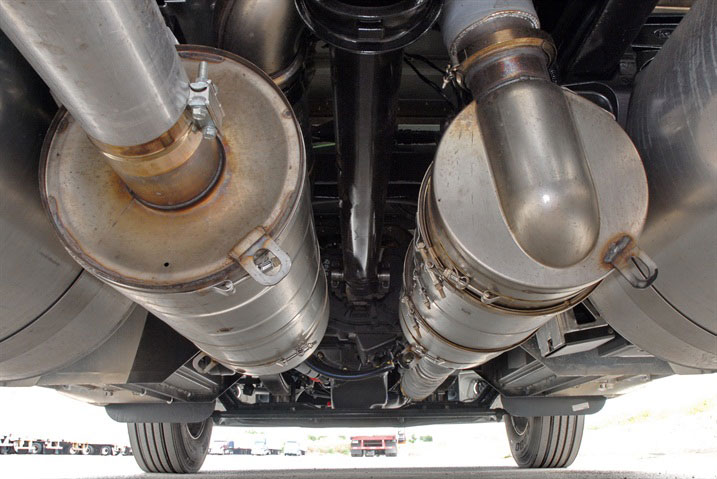

The primary components of a vehicle’s after-treatment system are the diesel particulate filter system (DPF), which reduces particulates, and the selective catalytic reduction system (SCR), which reduces nitrogen oxide (NOx).

The DPF system consists of the following:

Diesel Oxidation Catalyst (DOC) – The DOC reduces particulate matter and oxidizes carbon monoxide and hydrocarbons.

DPF – This filter is designed to remove more than 90 percent of particulates out of the exhaust.

The SCR system consists of these components:

Diesel Exhaust Fluid (DEF) – A solution made of urea and deionized water. DEF is introduced into the exhaust stream to reduce NOx emissions.

DEF pump – A part of the DEF delivery system that vacuums DEF from the tank, through the pump, filters the DEF and primes and maintains pressure between the DEF pump and doser.

DEF doser – The doser injects DEF into the exhaust system.

Decomposition chamber – This assists in mixing the exhaust stream with DEF prior to the SCR.

SCR – This is the catalyst for the chemical reaction that transforms the combination of the exhaust stream and decomposed DEF to meet regulations for NOx emissions.

The DOC and DPF work together at the front end of the system to reduce carbon monoxide and hydrocarbons, but more importantly, capture soot and ash in the exhaust system to reduce the risk of those particles reaching the atmosphere.

From there, the exhaust moves through a mixing chamber that introduces DEF … needed for the chemical reaction to reduce NOx in the SCR. The resulting ‘exhaust’ that gets reintroduced into the atmosphere is comprised of harmless nitrogen gas and water vapor.

In addition to the primary components of the aftertreatment system, there are also sensors. A differential pressure sensor estimates captured particles in the DPF. Exhaust gas temperature sensors monitor the system temperatures. NOx sensors measure the NOx conversion. PM (particulate matter) sensors, also known as soot sensors, measure particulates in the exhaust (mainly ash and soot). All of these sensors indicate when the after-treatment system needs repair or maintenance.

Diesel Particulate Filter

The key to maintaining a DPF is to ensure it’s able to regenerate itself when it fills with soot (triggering the warning light). The two types of generation include passive and active.

Inside the aftertreatment device (ATD), the exhaust first passes over the diesel oxidation catalyst (DOC), then passes through the diesel particulate filter, which traps soot particles. Passive regeneration happens when heat in the engine builds to the point where soot, or carbon, is combined with oxygen to create carbon dioxide. Since carbon dioxide is a gas, it can pass through the filter. Ash, on the other hand, is already a byproduct of combustion, so no amount of heat from the engine can convert it. Over time, the ash will build up to the point where the filter has to be physically removed and cleaned. This filter can then be reinstalled and reused. Passive regeneration occurs as the vehicle is driven normally under load; the driver is not aware that it is happening. It may not always keep the DPF clean over the course of the workday, so the filter may have to undergo active regeneration.

Passive regeneration is part of normal engine operation, however active regeneration requires the engine to take action. For example, a truck fully loaded with 80,000 pounds moving down the highway will create enough heat in the engine for a chemical reaction to occur—which is passive regeneration. Active regeneration takes place when the engine isn’t creating the heat it needs. For example, this may occur in a truck that’s not fully loaded. Once the soot level reaches a certain point, the engine injects fuel into the exhaust stream, which goes over the oxidation catalyst and oxidizes the fuel to create heat. The heat created from the fuel oxidizing is then used to convert soot to carbon dioxide.

Both active and passive regeneration happen automatically and without driver input. Active regeneration can occur automatically any time the vehicle is moving. The exhaust gas temperature could reach 1500℉ (800℃).

Active regeneration is unknown to the driver with the exception of some additional dashboard lamps. The biggest sign to look for to determine if it is taking place is the high exhaust temp light, which will turn on once the aftertreatment doser starts to inject, increasing the temperature in the aftertreatment device.

When operating conditions do not allow for DPF cleaning by active or passive regeneration, the vehicle may require an operator activated parked regeneration.

In order for this to take place, the vehicle must be standing still. The driver or technician brings the engine to operating temperature and initiates the parked regeneration by activating the dash controls. This may take anywhere from 20 minutes to an hour, depending on ambient conditions and type of engine or DPF system.

It’s critical for the driver or technician to ensure the exhaust outlets are directed away from structures, vegetation, trees, flammable materials and anything else that may be damaged or injured by exposure to high heat. Not all DPF systems have a parked regeneration feature.

How much does it Cost to Replace a Diesel Particulate Filter?

Replacing a diesel particulate filter can be pricey. A new filter from a car manufacturer can cost anywhere from $2,000 to $10,000.

It’s no secret that as cars and trucks age, their value decreases. Oftentimes, the price associated with replacing a DPF in an older, higher-mileage car or truck is more than the value of the vehicle itself. It’s much easier (and more affordable!) to clean a diesel particulate filter than it is to replace it, which is why understanding how these filters work and performing regular maintenance is so important.

If a parts supplier charges less for a DPF, be wary—the filter must be the correct type for your vehicle. Otherwise, you will most likely end up spending more on repairs.

What Our Clients Have Said

Our Story

I would like to introduce myself and tell you a little about my background. My name is Peter Golove. In the past, I was a truck owner-operator. I also had some experience in mechanics but wasn’t very interested in advancing it. All those years that I spent driving gave me experience and knowledge about trucking. It also taught me how difficult and demanding this business can be. Dealing with all the regulations, police, poor-quality mechanical services, and dispatchers all by yourself can be overwhelming. Nobody really appreciates how hard you work and how tired you might be. Every company you work with cares about timely delivery. What they don’t take into account are your rest and sleep hours, and emergency situations. Any machinery can break at any time, and trucks are no different. While driving my truck, I faced many technical and computer issues for which I was overcharged, and it didn’t necessarily fix the problem. It turns out, 90% of the time, the issue was in the Aftertreatment system. I started looking into it and learning all about the Aftertreatment system. One day, I opened a shop for any type of Aftertreatment systems. Our shop has been providing full Aftertreatment system services for more than 10 years in the Diesel Emission Industry. Our shop strives to improve services and customer satisfaction. We provide services for big companies, such as Walmart, Amazon, FedEx, and Landstar, to name a few. Aftertreatment systems can prevent many other issues if they are regularly serviced and well maintained. Save yourself time, money, and hassle, and let us take care of your truck so you can take care of yourself and your family. Our great team of mechanics will treat you as family and will help you with everything you need.

Our Business Clients

Gallery

DPF Re-Core Gallery

Videos

Contact Us

Monday-Friday: 8:00 AM 6:00 PM Saturdays: 8:00 AM-12:00 PM Sunday: Closed

- 2202 Manana Dr #212 Dallas, TX 75220